POSITIONING

New - NTP-3000ECO:

The NTP-3000ECO automatic ruler is a device based on the NTP-3000 ruler, which was appreciated by customers. Market research revealed a niche in cheaper solutions that would not be inferior in functionality and quality to more expensive models. This is how our design department designed a new rule in an economical version - NTP-3000ECO, which we can offer for PLN 14,999 net. For this price, we will get a 3-meter-long machine with a full galvanized steel top, a bumper with adjustable extension that allows for cutting even small elements, and a large 7-inch HMI touch panel.

We can additionally equip the measuring device with:

- label printer,

- barcode scanner,

- wireless measurement with transmission from the Nedo mEsstronic ruler,

- wireless measurement with transmission from the NMT-BTronic ruler

- hand raised bumper,

- pneumatically raised bumper,

- reading cut lists from a pendrive,

- reading cut lists from the LAN

- roller top,

- metal/roller top

- stainless steel top

- communication module with the machine (for service purposes)

Technical specification:

- Working width:: 3000 [mm] możliwość wykonania do 6000 [mm]

- Table height: 850-910 [mm]

- Bumper drive speed: 1 [m/s]

- Positioning accuracy: +- 0,25 [mm]

- Touch screen panel: 7' touch screen

- Working table:

- full top (standard)

- roller top (extra)

- metal/roller top (extra)

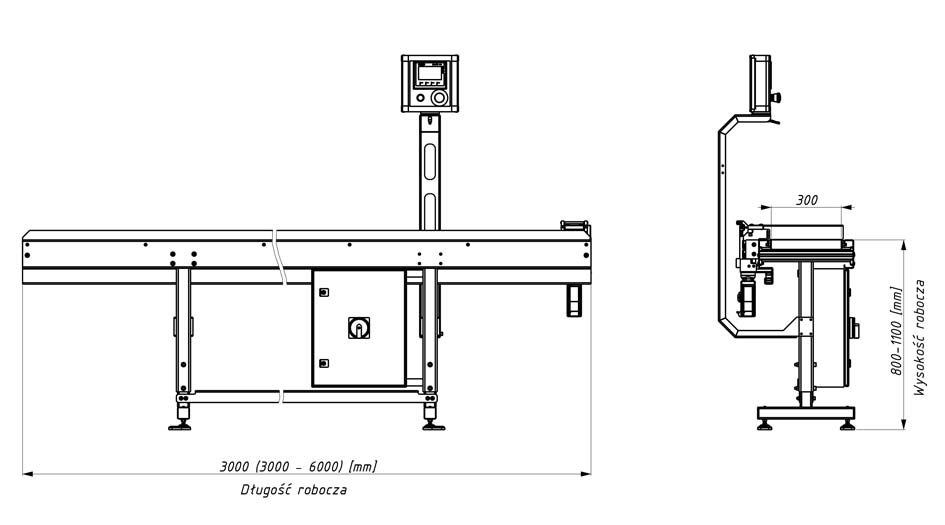

Automatic measuring device NTP-3000:

The NTP-3000 automatic measuring device is a device for precise determination of the length of cut materials, which is characterized by:

- Supporting structure made of steel profiles - welded, powder coated for high rigidity, anti-corrosion resistance.

- Bumper mechanics - line rails and Bosh REXROTH carts - a brand that is characterized by reliability, long life, trouble-free operating time.

A drive system was used on a precision toothed rack - positioning accuracy 0.2-0.5mm on the full length working. Hardened toothed lists ensure longer life, maintaining positioning tolerance.

Siemens automation - reliability, quick availability of spare parts to facilitate service, expandability of the system for peripheral devices (label printer, scanner). Automation leader on the market.

Wireless keypad - the possibility of remote control from the working area of the saw, preview of the current dimension values on the panel.

Single-phase power supply - can be installed in places without power supply.

Control panel - clear, intuitive menu, panel on the swivel arm located at the operator's eye level (ergonomic position). Thanks to the parameters /

corrections we can adjust the operation of the measure to each saw.

Adjustment of the bumper is done by entering the dimension in the touch control panel or using a wireless keyboard, there is possibility of adding an electronic measuring module (e.g. measuring the glazing bead directly on the window) and radio sending dimensions to measure (additional option).

Each machine has a CE declaration, Polish manual and a warranty.

Technical specification:

- Working width:: 3000 [mm] możliwość wykonania do 6000 [mm]

- Table height: 800-1100 [mm]

- Bumper drive speed: 1 [m/s]

- Positioning accuracy: +- 0,2 [mm]

- Touch screen panel: Panel obrotowy z wyświetlaczem dotykowym oraz klawiaturą bezprzewodową (możliwość dodania elektronicznego modułu mierzącego). Pozycja panelu obrotowego wg. wskazania klienta (lewa-prawa strona).

- Working table:

- blat pełny (standardowe wykonanie)

- blat rolkowy (opcja dodatkowa)

- blat rolkowo-pełny (opcja dodatkowa)

SEND US

Fill out the form below. We provide you with the offer best suited to your needs.

* Fields are an asterisk are required.

NEMITECH Sp. z o.o.

ul. Poligonowa 22, 18-400 Łomża

tel/fax: +48 505 420 211

e-mail: nemitech@nemitech.pl

Sąd Rejonowy w Białymstoku, BI.XII Wydz. Gosp. KRS 0000672779, NIP 7182145994, REGON 367001883, Kapitał zakładowy: 50.000,00 PLN